Manufacturing process

The core of Sanko Seisakusho

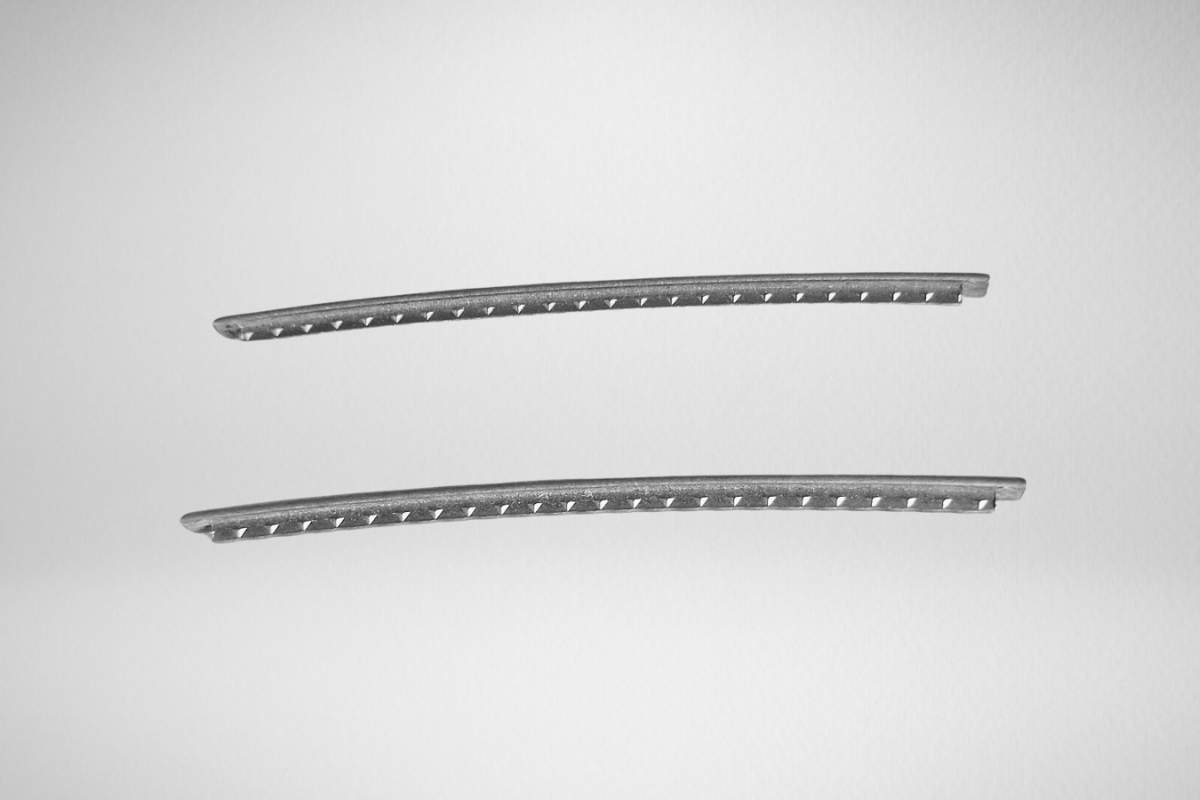

We were one of the first companies to commercially manufacture frets for stringed instruments and supply them as our original brand.

Our frets are also used as OEM products by many guitar manufacturers.

We have earned a worldwide reputation for innovation, quality, and reliability in the field of precision deformed wire.

Using our unique tooling and sophisticated techniques we shape and create irregular and ultra-fine wires to precise tolerances.

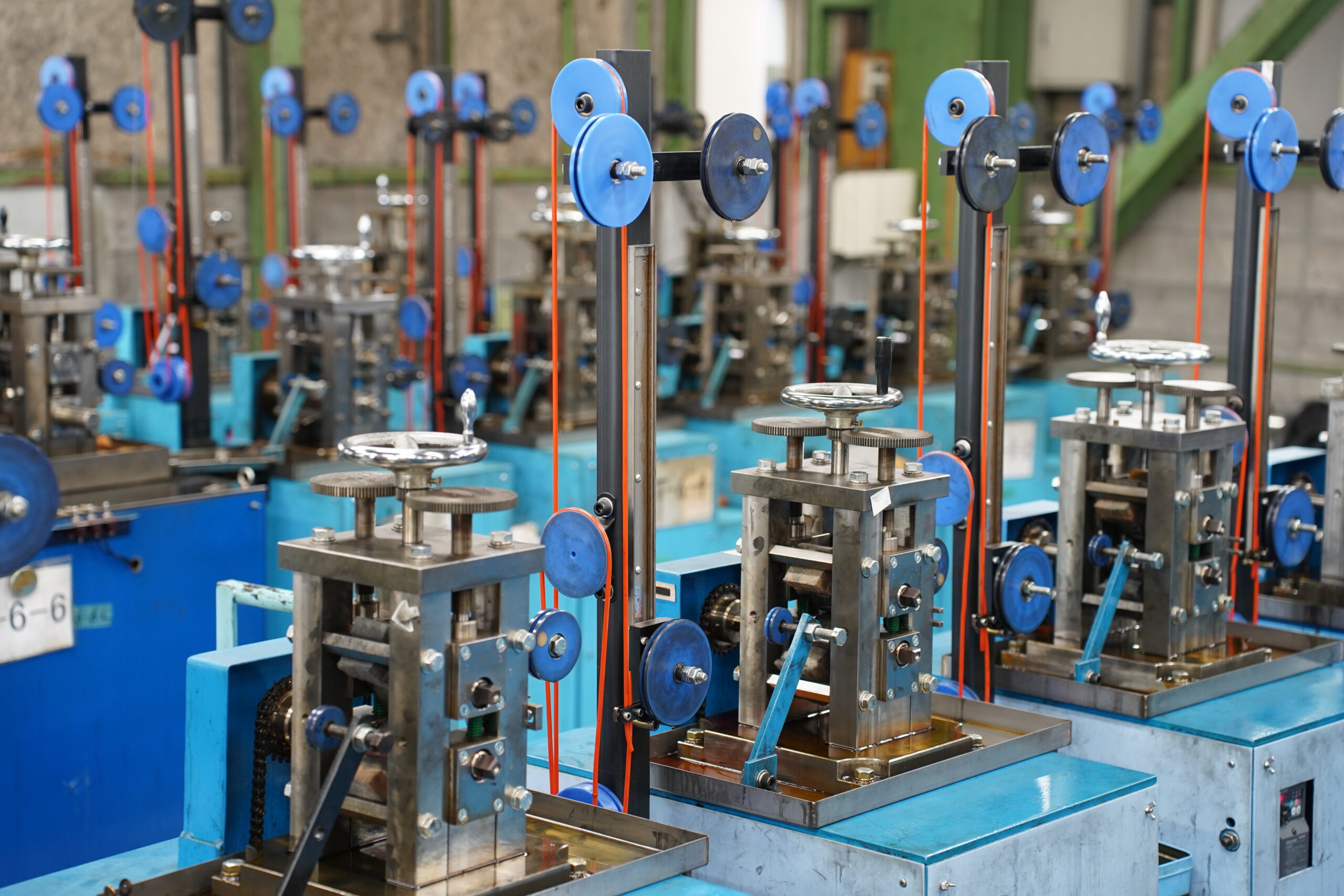

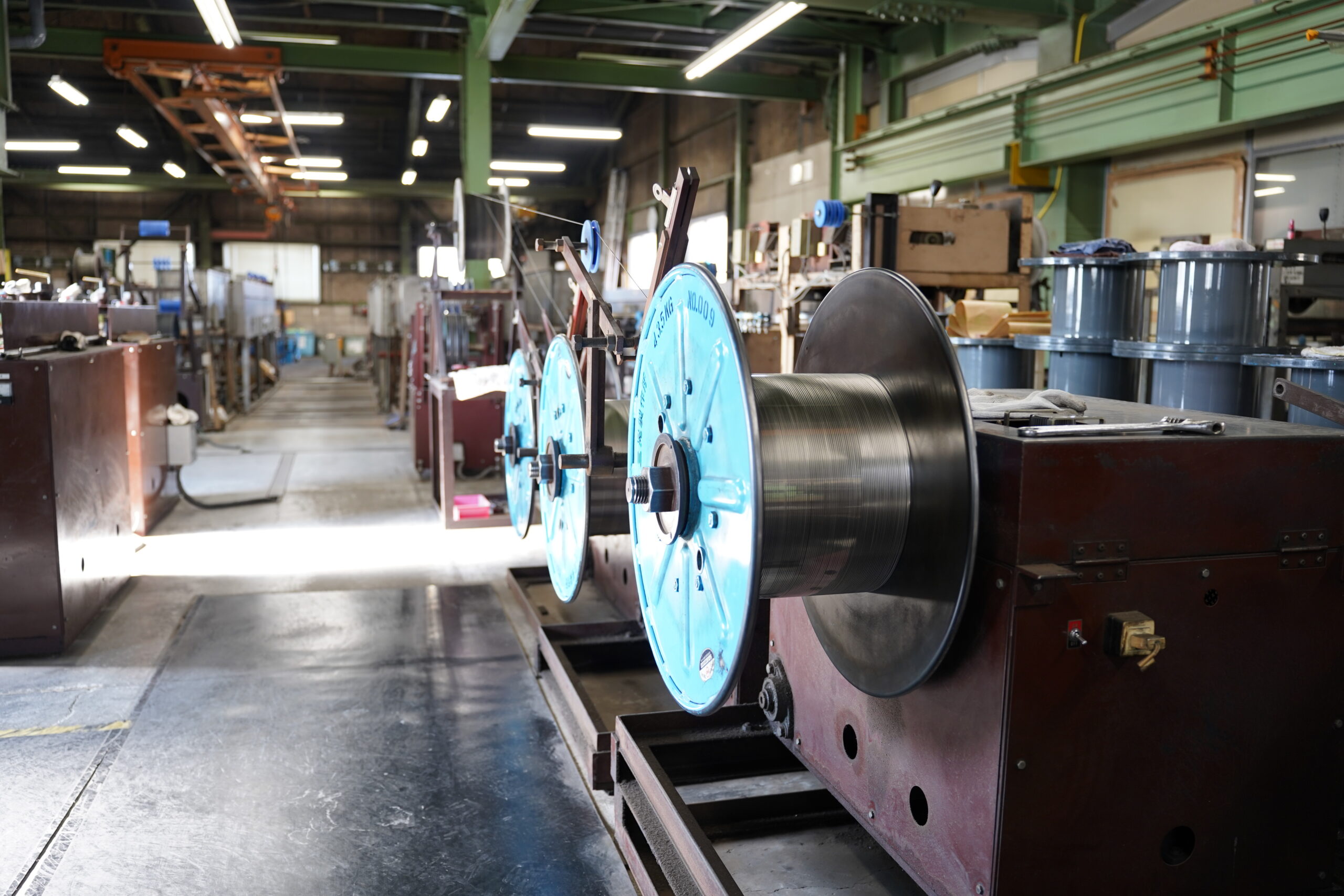

From rolling to cutting to QA inspection, all steps of the manufacturing process are performed in-house. This supports high quality products and small-lot production.

With quality assurance integrated into the manufacturing process, our products are recognized for their reliability and level of quality.

We don’t simply “make” things.

We aim to achieve the highest level of quality and supply stability.

Armed with our unique technology and knowledge,

we will continue to pursue “manufacturing that is needed in the world.”

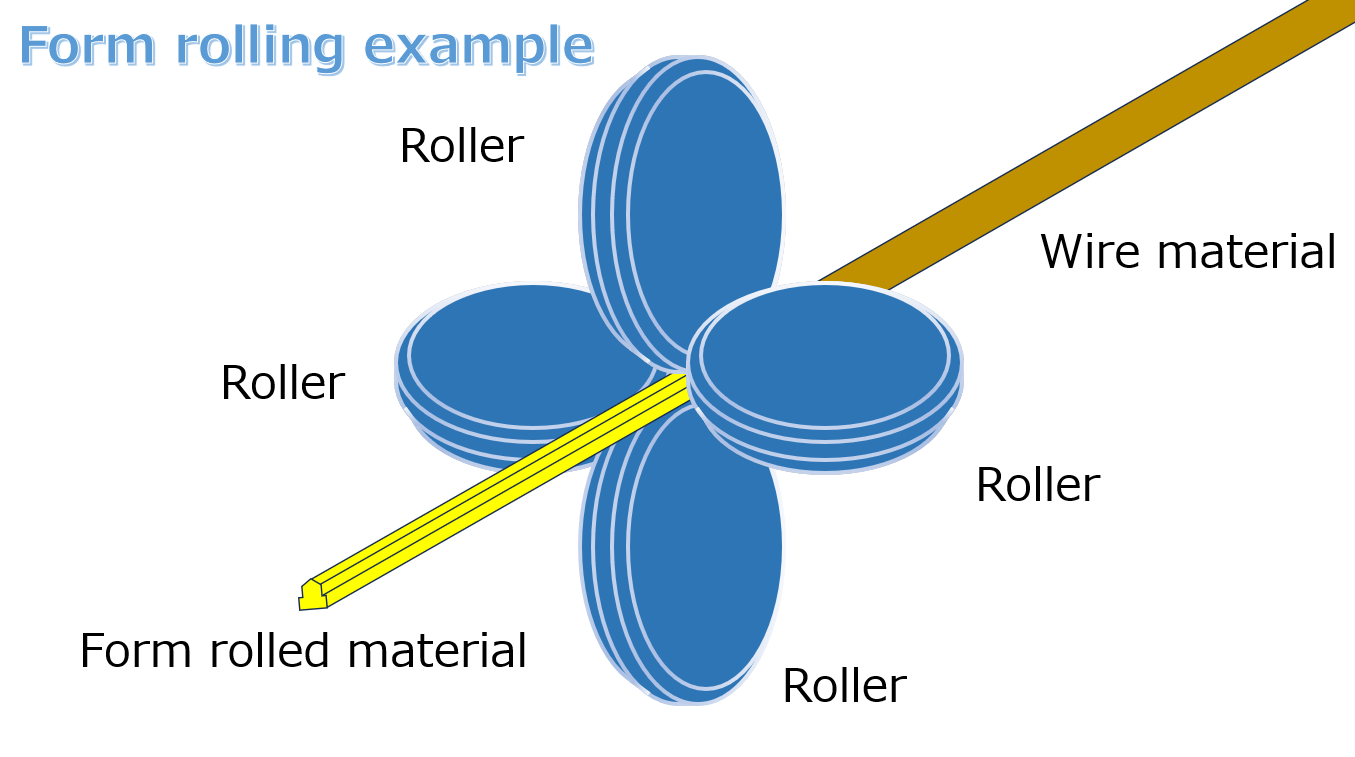

What is form-rolling?

Form rolling is a processing method in which metal wire or bar-stock is passed between opposing rollers and compressed into a thinner or irregular shaped material. All flat wires and irregularly shaped wires are manufactured using the same process.

How its made

01

Material

All materials start out as round wire

02

Profile

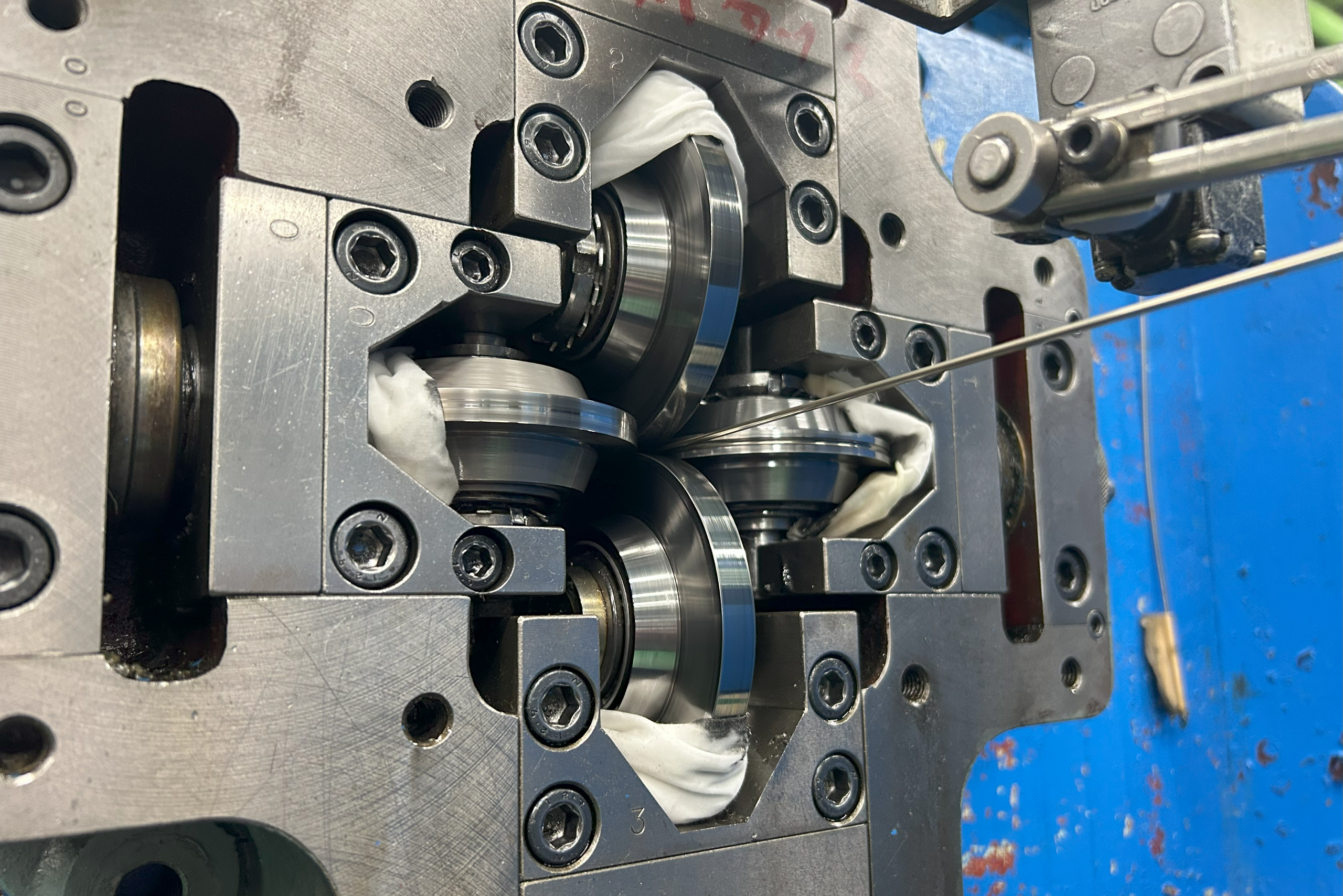

We in-house machine all our roll dies, which allows us to create unique shaped wires for various customers with little to no down time.

03

Rolling

Utilizing cold rolling techniques, we select the appropriate rolling machine to create the desired shape while meeting the specified tolerances.

04

BA(Bright anealing)

Using our in-house developed reel-to-reel bright annealing furnace, we are able to treat various metals to meet different hardness specifications as well as surface finishes.

05

Cut

We can process wire in a variety of ways to suit your needs.

06

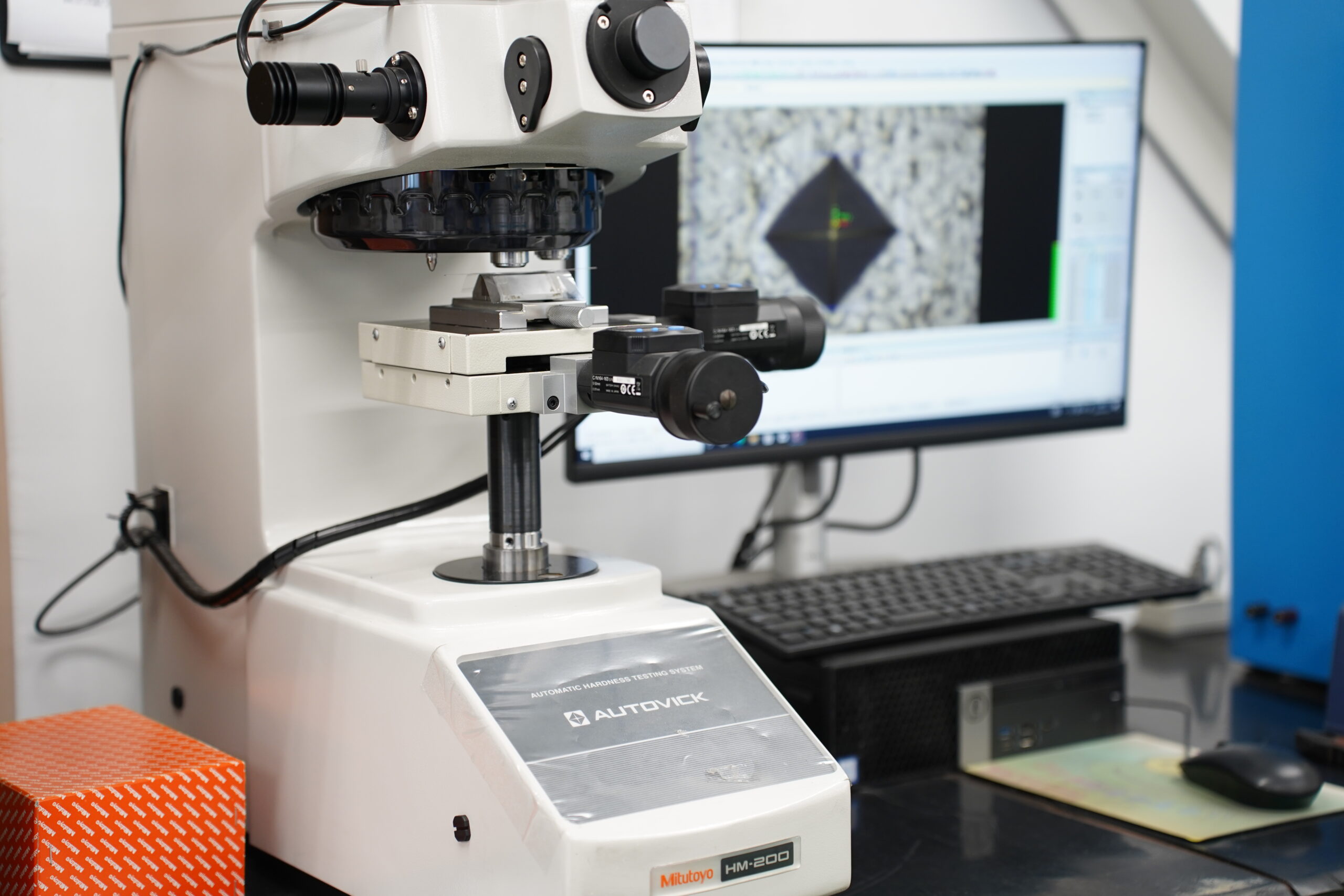

Inspection

We check and inspect all materials using various inspection tools, such as: Vickers hardness tester, profile projector, tensile tester, etc. to certify and guarantee the specifications meet the customer’s request.