Reason for joining the company

I used to work at a metal fabrication factory that manufactured office supplies.

It was very difficult to see what the products would ultimately be used for, which made it hard to stay motivated.

I love guitars and music, and so my wife told me about a company that makes guitar frets. I am familiar with frets since I play guitar, and I thought a career where I make them would be interesting. With these reasons I decided to make the transition and joined the company.

Creating a product that’s invisible

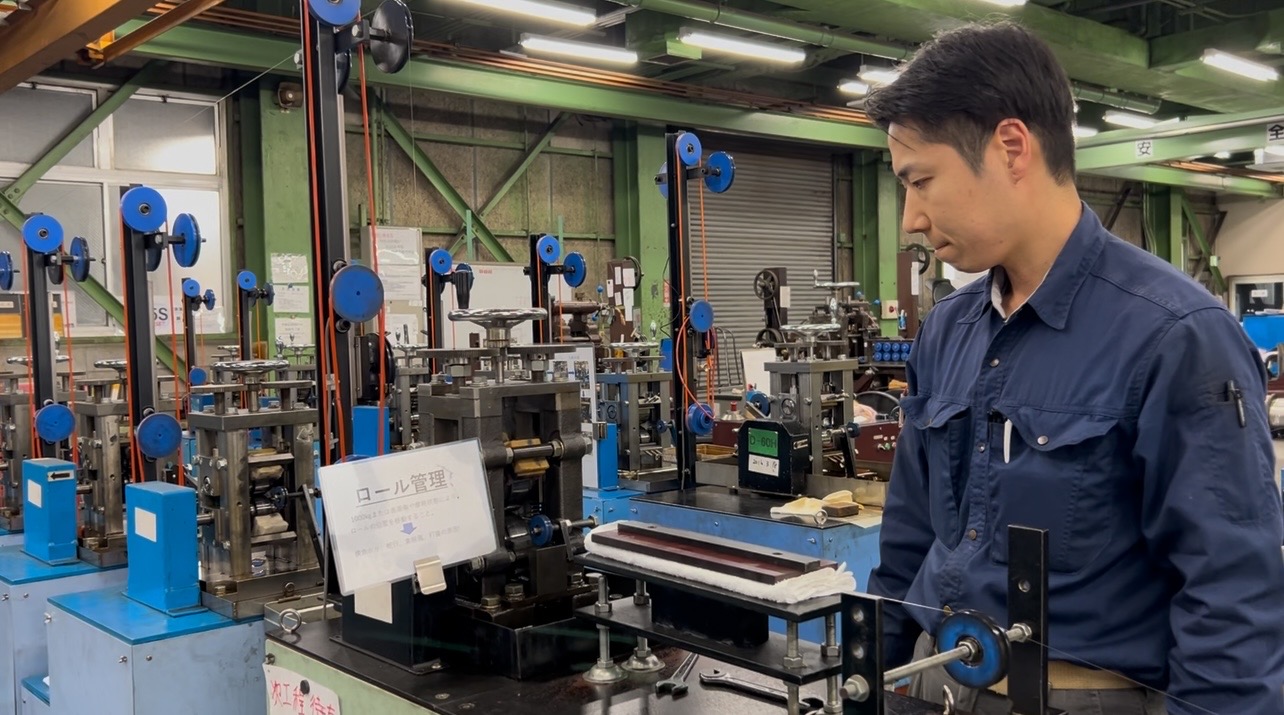

I am currently in charge of rolling flat wire. Some applications for flat wire are springs, connector parts, and piston rings. There are especially many parts for automotive equipment. The wire rolling process is a lot more complicated than it may seem. It is not just crushing or flattening the metal; it’s about understanding what you are creating and all the conditions involved, i.e. material type, material hardness, surface finish.

Under the same conditions, slight differences in materials can produce completely different results. Therefore, even if you follow the manual step by step, it may not work. You’ll need to utilize your experience and intuition. Sometimes you’ll find that, “it worked yesterday, but for some reason it doesn’t work today.” If so, then we will need to make corrections through “trial-and-error” and ultimately create the product that meets or exceeds our standards.

For my first year with the company, I was fortunate enough to work in quality assurance. Having that experience testing and inspecting our products, I was able to understand “which parts are important in this product” and “which parts should be carefully manufactured.” My experience in quality assurance was very useful when I moved to the manufacturing floor, because it helped me understand the finished products’ expectations.

The “fun of manufacturing” that lies beyond trial and error

One of the most rewarding parts of this job was when I successfully completed a difficult project that in the beginning made me wonder, “Can we really do this?” Completing jobs like that give me such a sense of satisfaction and assurance, knowing that “we can really do this!” One example that comes to mind is, I was once asked to work on a product that was extremely difficult to process. It was the first time we processed this material to this specification. At first, I thought “How can we make it, if it is so curved?” However, after much trial-and-error and encouragement, I was able to give it shape and meet that specification. I felt such a great sense of accomplishment.

During the rolling process, sometimes we encounter something called the “no-no” period, in which the metal exhibits resistance to processing. How we approach and control this situation is very important. Once the “no-no” period begins, the metal will try to return to its original shape no matter how hard we push it, so you will have to make adjustments at the optimal timing. This is extremely difficult and requires a different response each time.

I feel that this job is not just a task that can be accomplished. It’s that a craftsman because it requires experience, intuition, originality and ingenuity. It is both fun and challenging to hone your skills through daily trial-and-error.

I will continue to hone my skills and to produce higher precision products.